|

|

Software Development

As a full-service software and design firm, AD Automation is providing software development services. Our team of engineer design and build software applications, and they have expertise in developing windows applications, programming PLC logic and Designing Human Machine Interface programs.

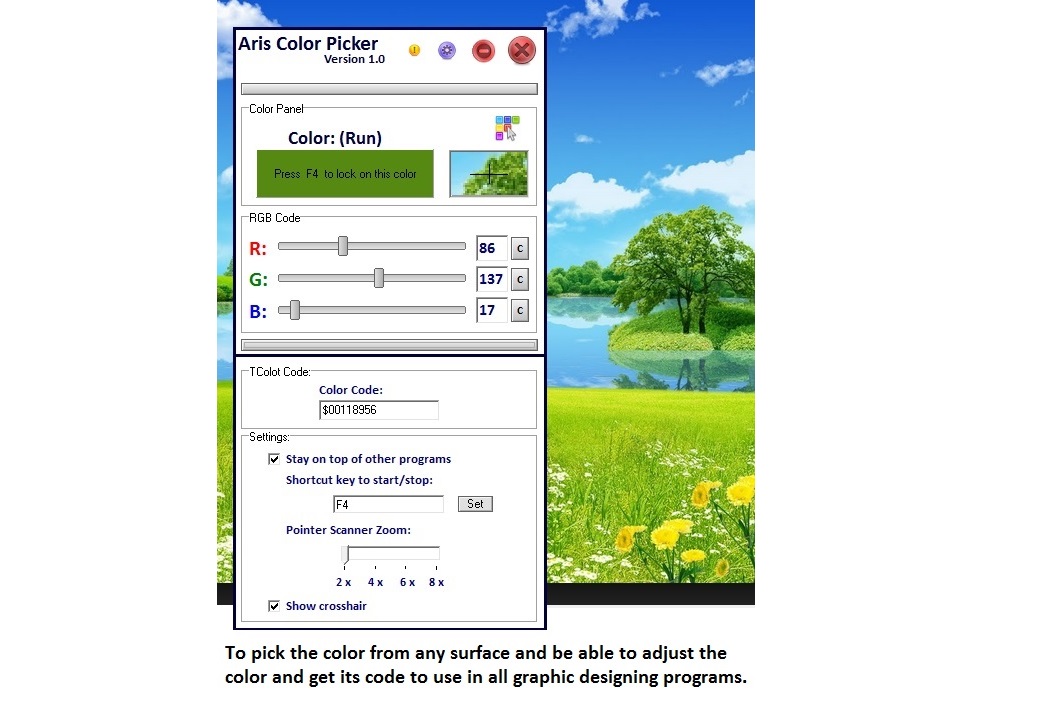

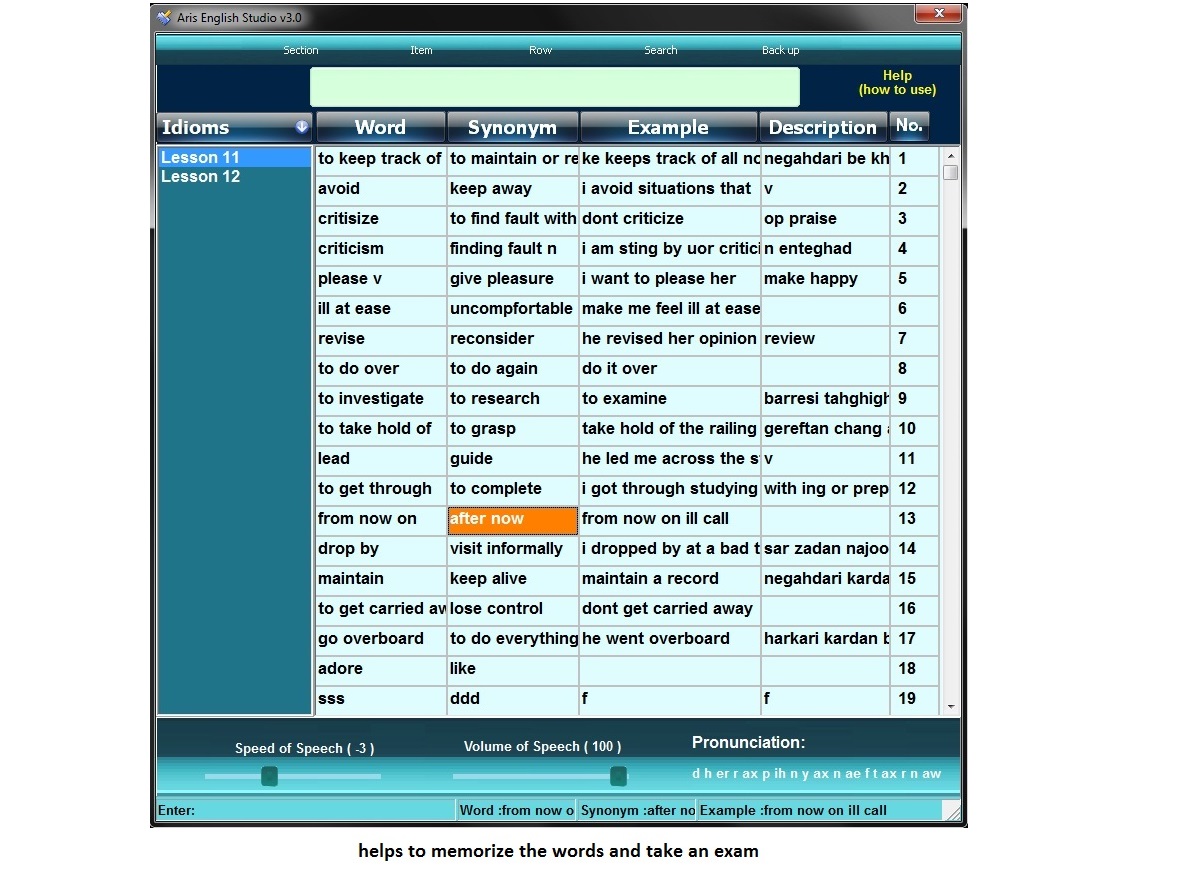

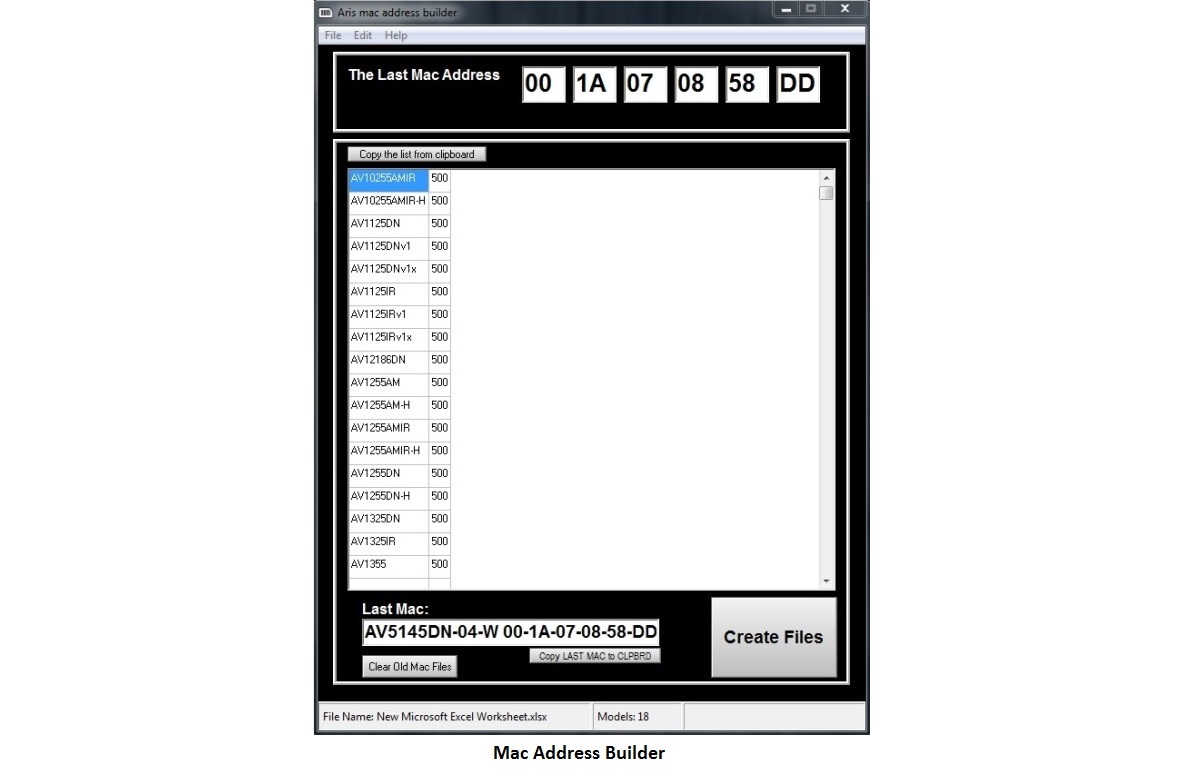

Here is a list of some programs with their images:

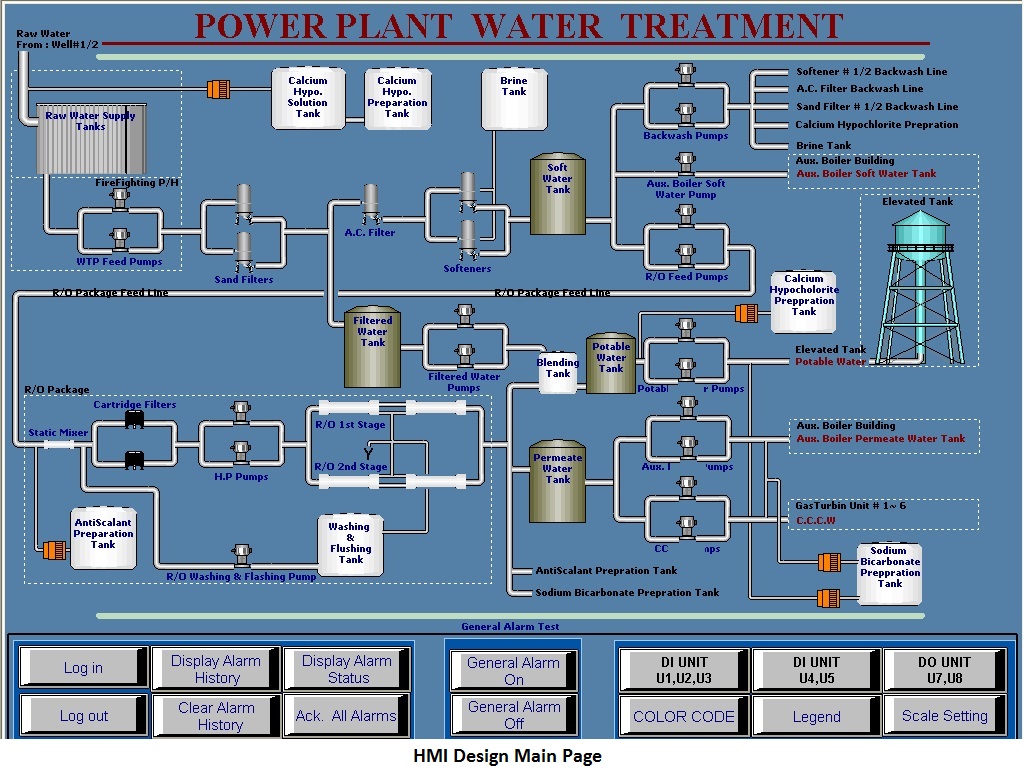

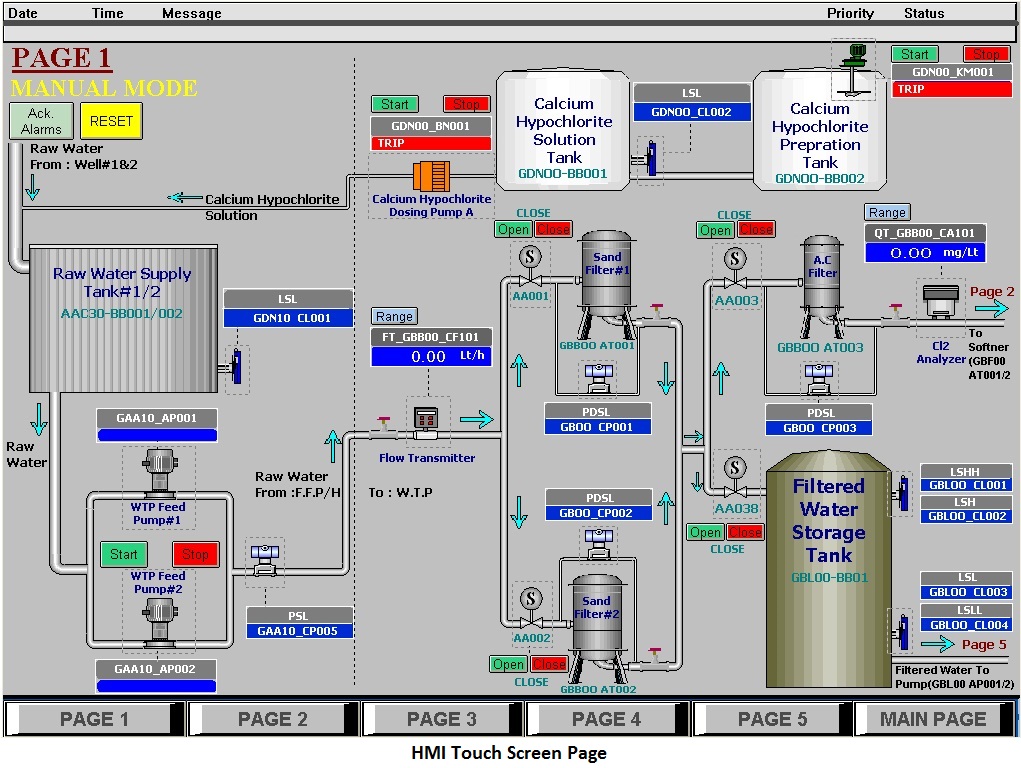

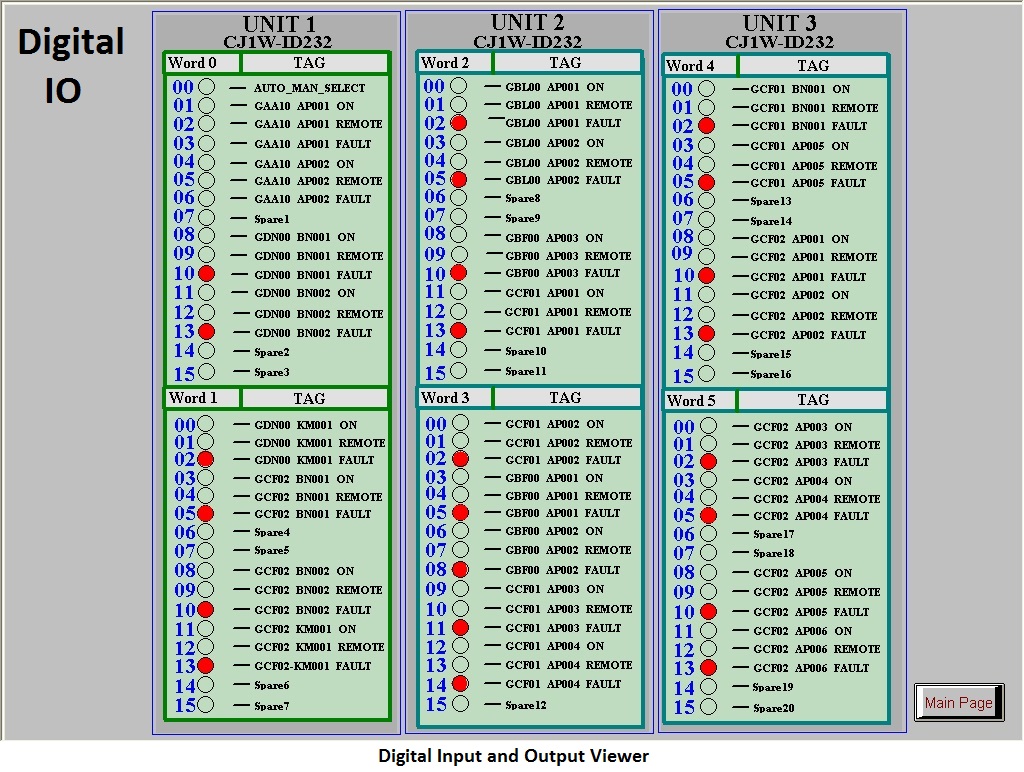

Programming PLC and Designing HMI:

Our programmers are capable of programming a wide variety of PLC brands and models. They would do:

- Control Logic for most of the PLC vendors.

- Programming PLC ladder code in all PLC program environments.

- Operator interface designing. (HMI on graphical touch screens)

- Fully documented control logic programs.

- PID loop control programming and tuning.

- Graphical animation of process data.

- VBA programming for windows operating system.

Below are some sample images of projects:

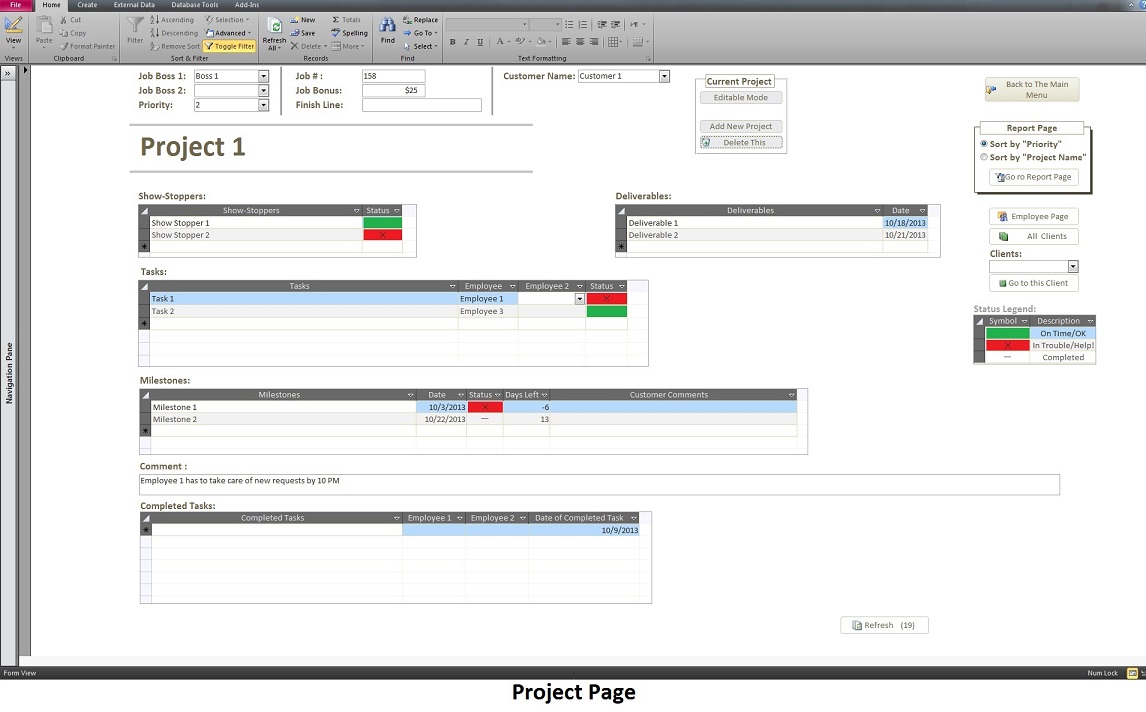

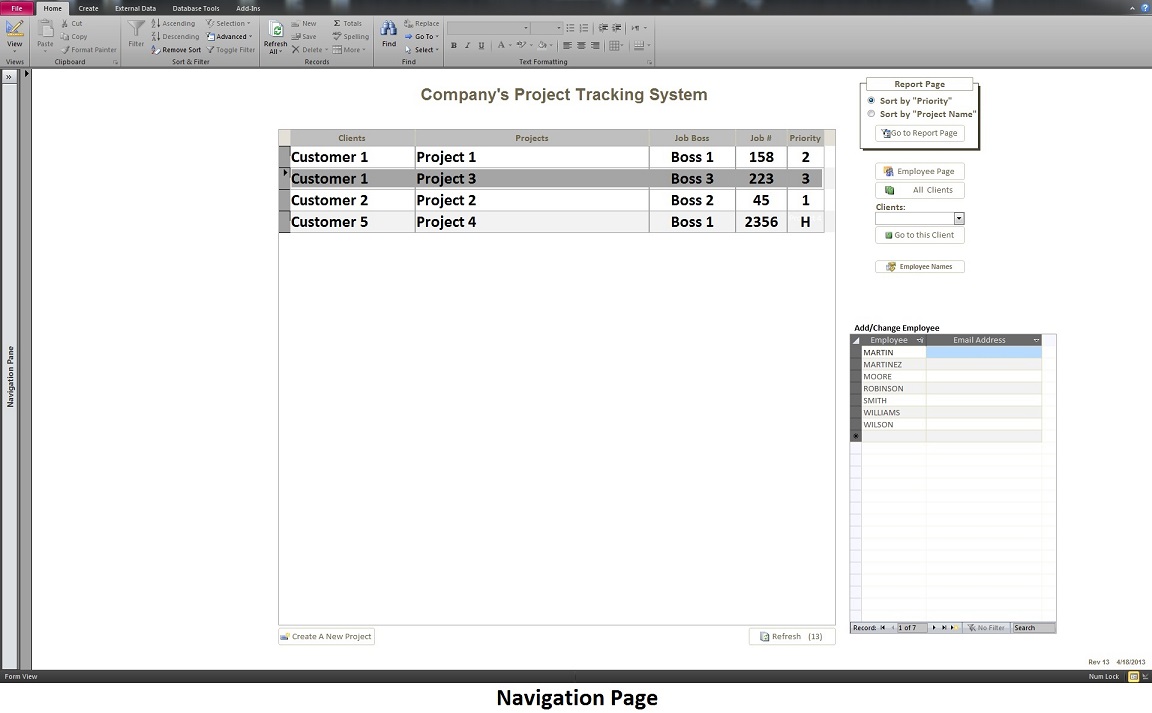

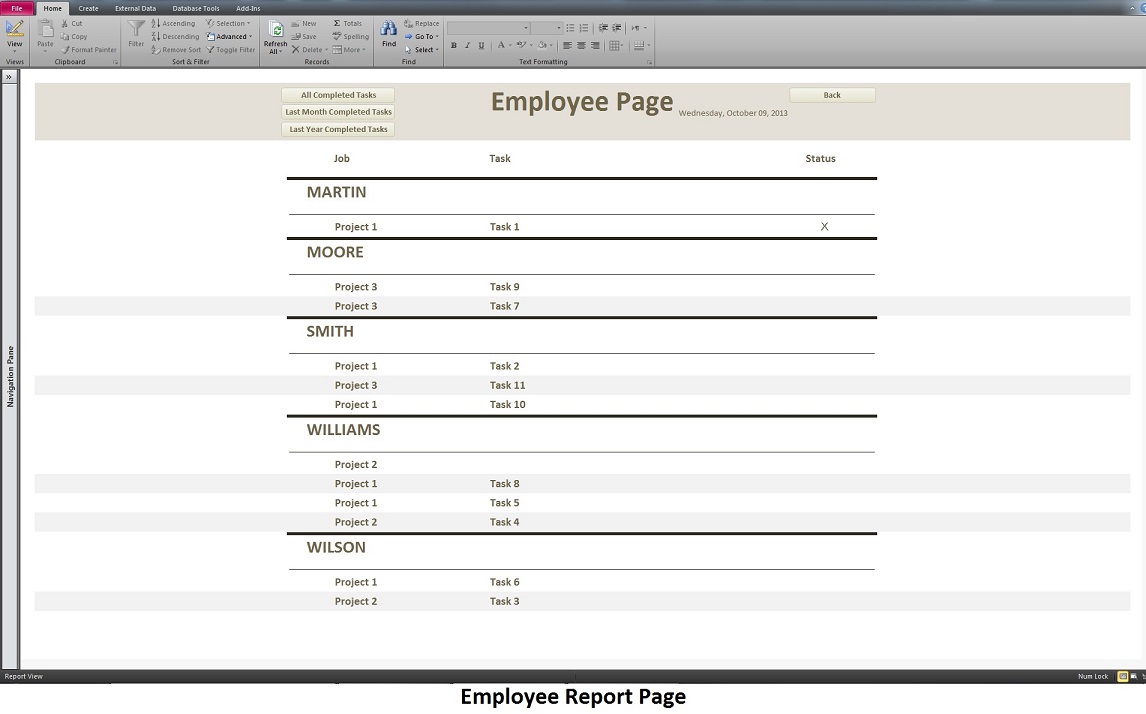

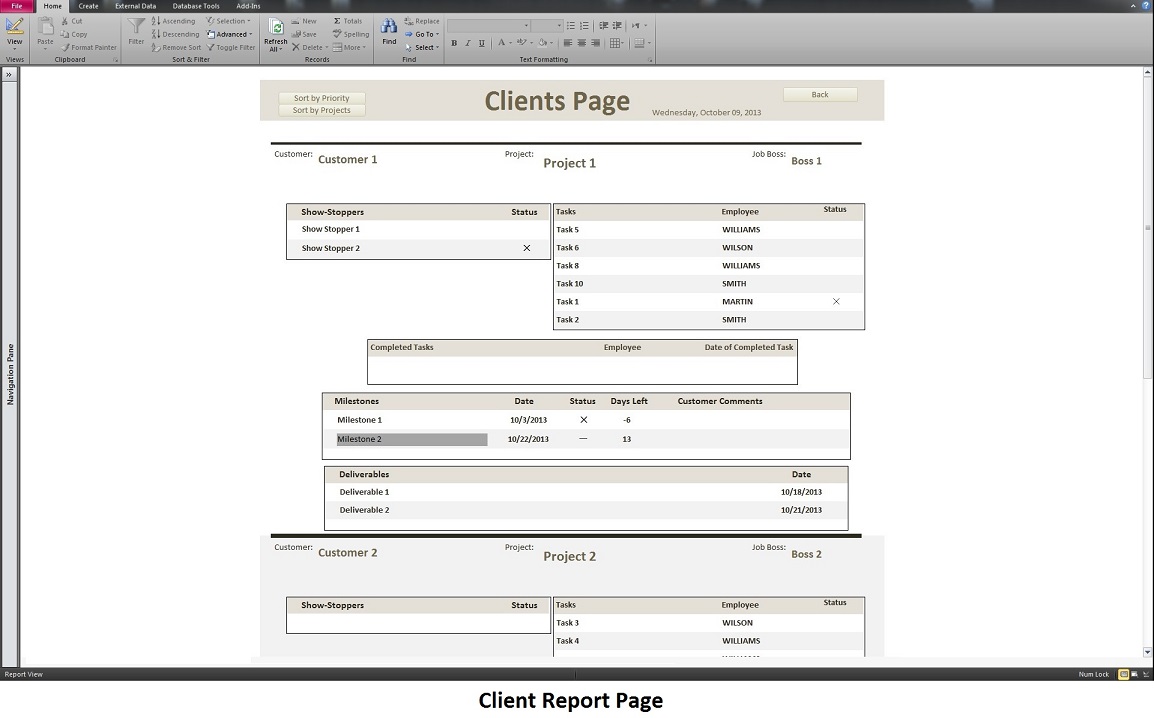

Project Tracker:

Project managers and some employees are often required to keep detailed metrics on a project's status. The compilation of that data usually places a large demand on all employees and managers, who are often already squeezed for time. We create customized project tracker database to track time-sensitive deliverables, employee roles, and vendors using Access or SQL Databases. Navigate by project, deliverables, and employees, keep an eye on budgets, owners, costs, and status, and generate focused reports such as Project Balance Sheet and Deliverables by Assigned To.

Project tracker databases make it possible to:

- Collaborate on Projects

- Delegate Tasks

- Stay on Schedule

- Track Projects

- Provide a Snapshot

- Provide a report

Below are some sample images of projects:

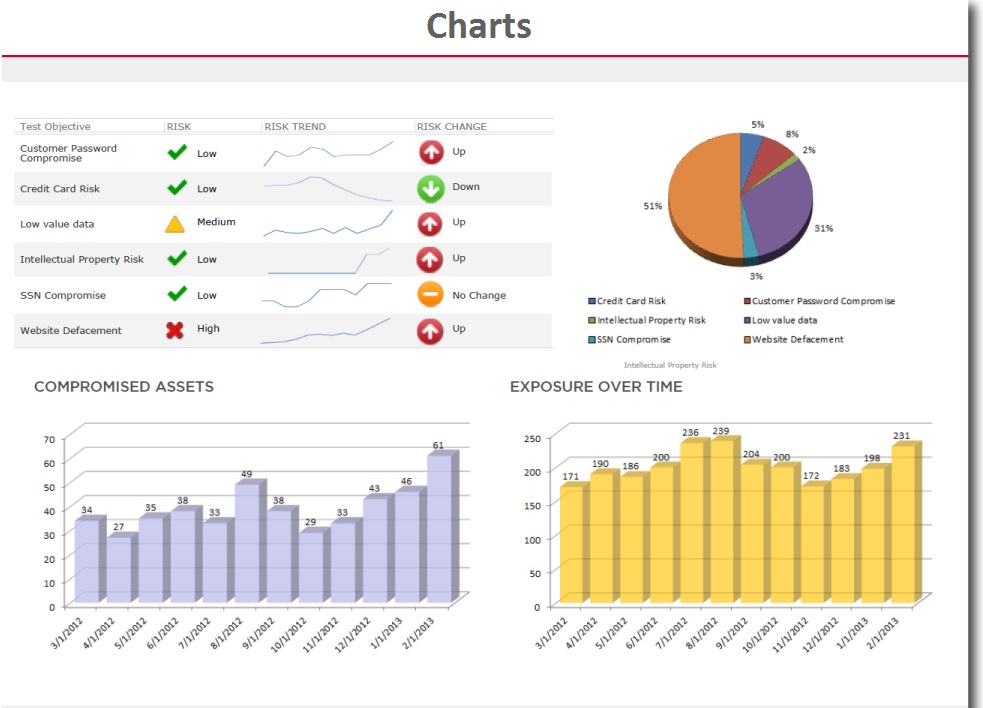

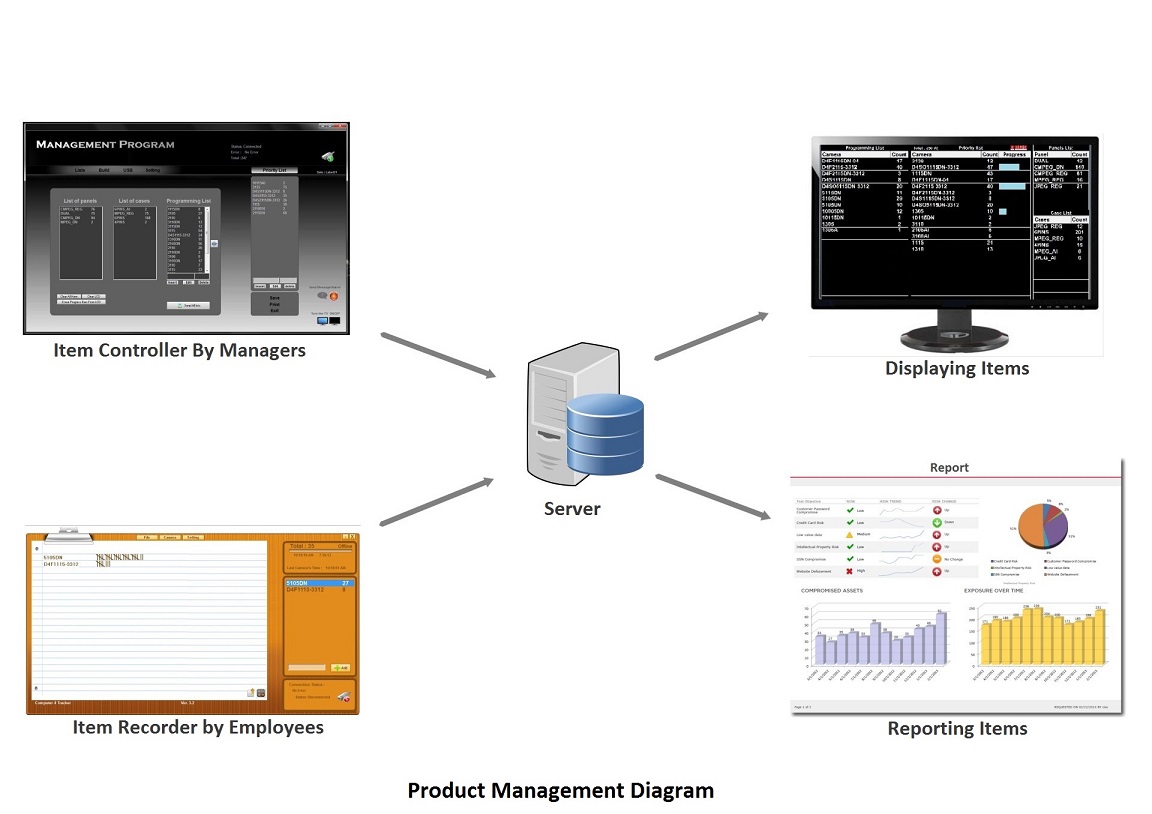

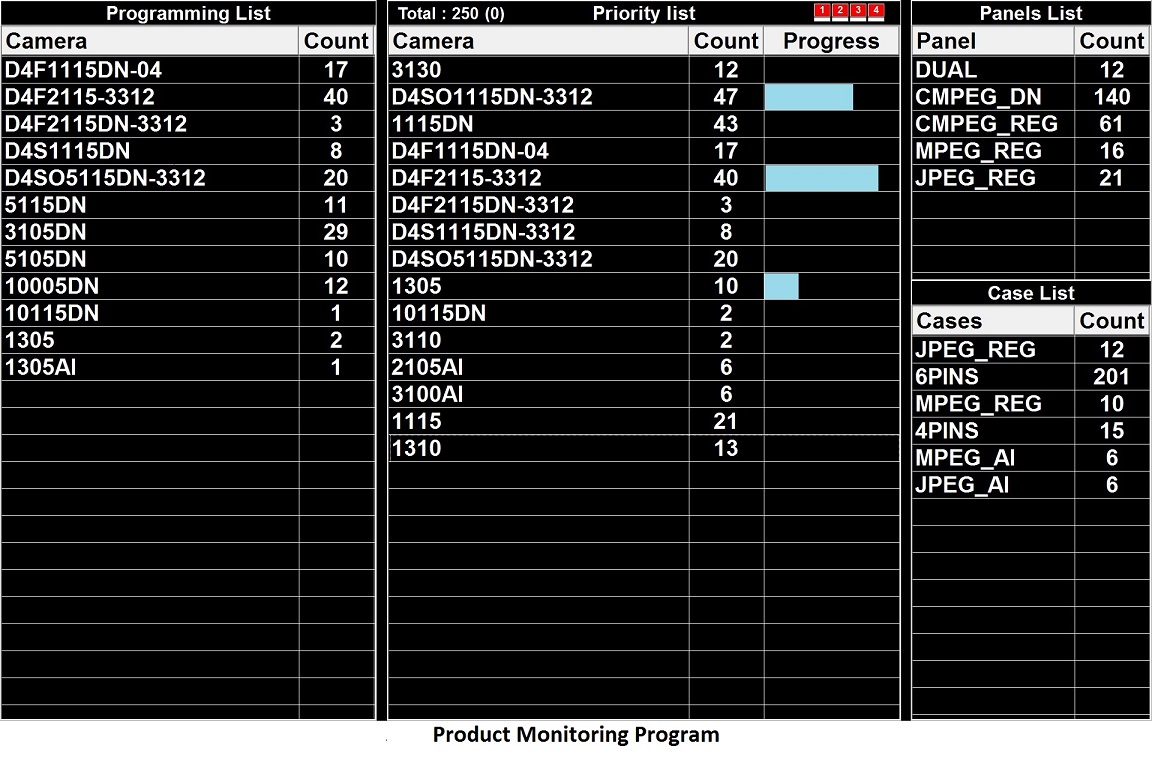

Product management software:

Project management contains some windows applications for tracking/managing all type of products. Windows Applications must provide tools for planning, organizing and managing resources to achieve production goals and objectives. The project management software can be accessed through an intranet or WAN / LAN. The software can be ease of use with access control features (multi-user).

- Controlling all the displays in production lines

- Displaying priority orders by different colors on the screens (Red – High priority, Grey – On holds and etc.)

- Calculating leftover materials count for each week.

- Getting the report and feedback how many products are built from the production line in real time.

- Capable to control the production line from other ISP’s or Home internet.

Below are some sample images of projects:

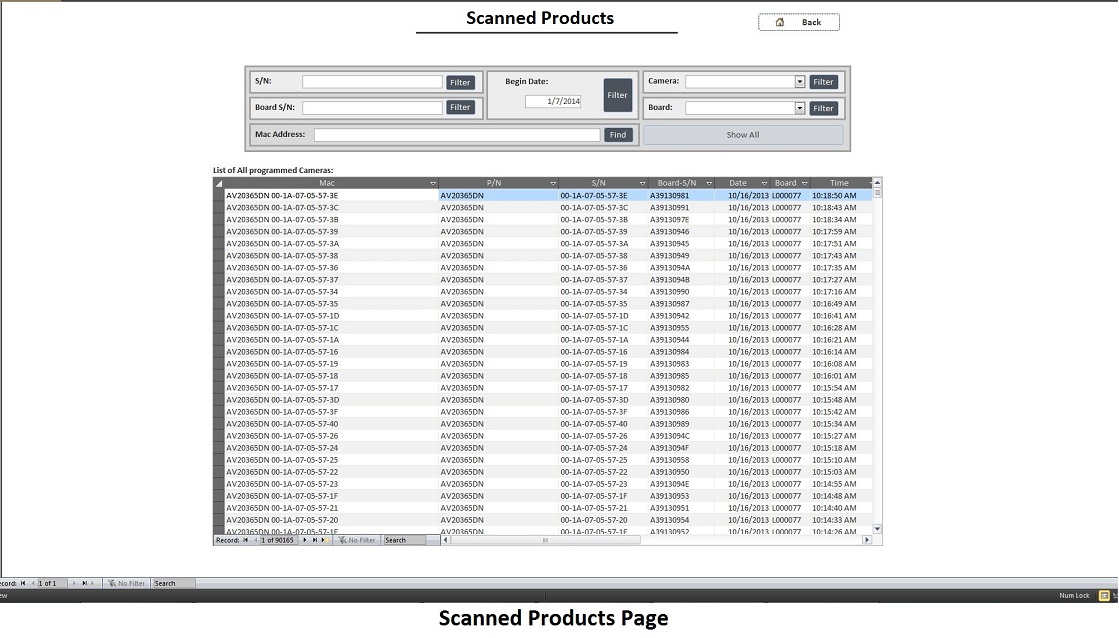

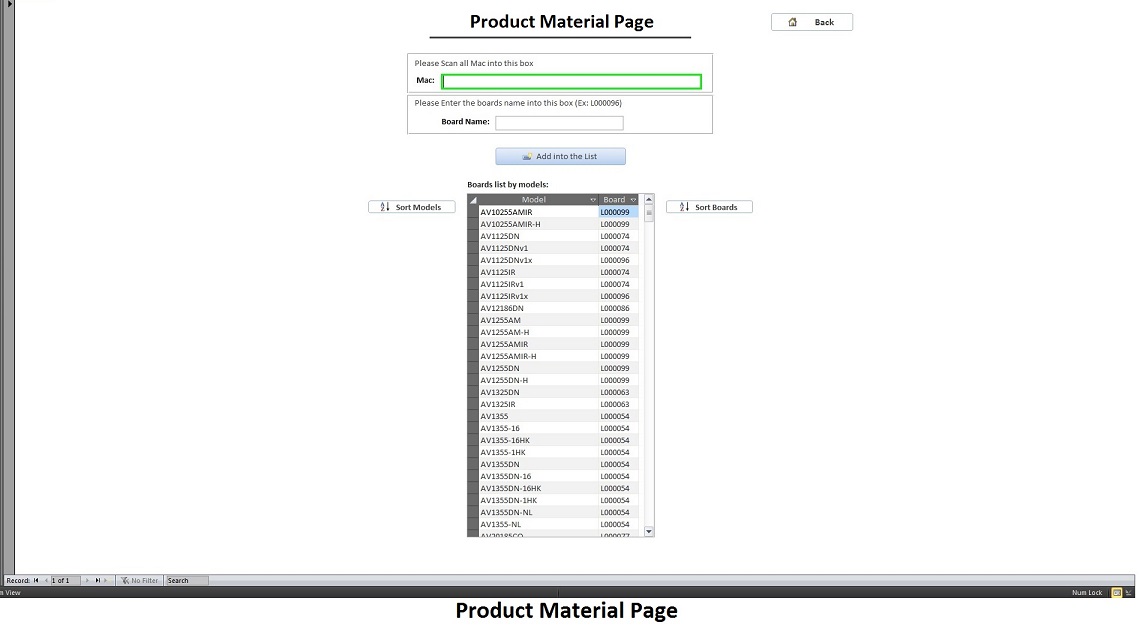

Product scanner:

Description: This application creates and manages all the built products in all production lines with all the relevant minute details such as product’s model, serial number, the date, operator’s name, and much more.

Important Features:

- All the Applications are connected to each other using LAN. It detects duplicate serial numbers and avoids building them.

- It detects wrong and bad mac addresses.

- Easily categorize the entire range of boards for relevance and convenience.

- Track, sort, view or manage our scanned materials much more effectively.

- It saves all the history of models and dates in the Database.

- It is a lot faster and saves time to scan Products.

- It detects what period of the time the products are built by scanning the mac address simply.

Below are some sample images of projects:

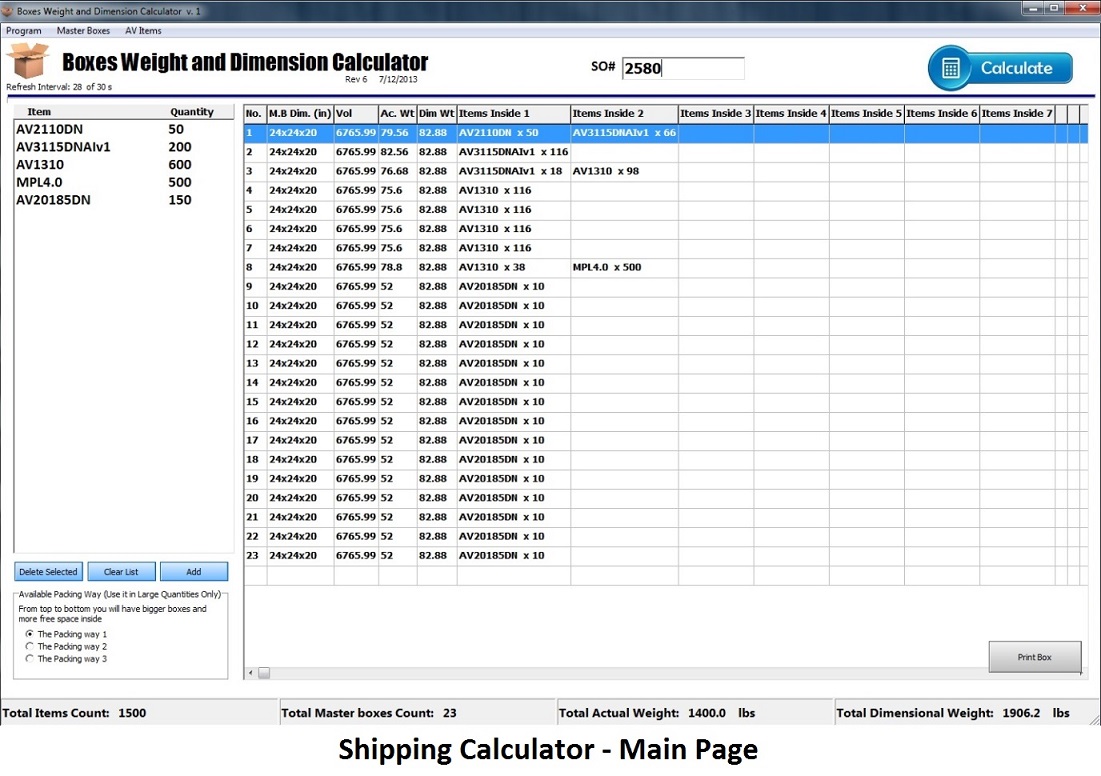

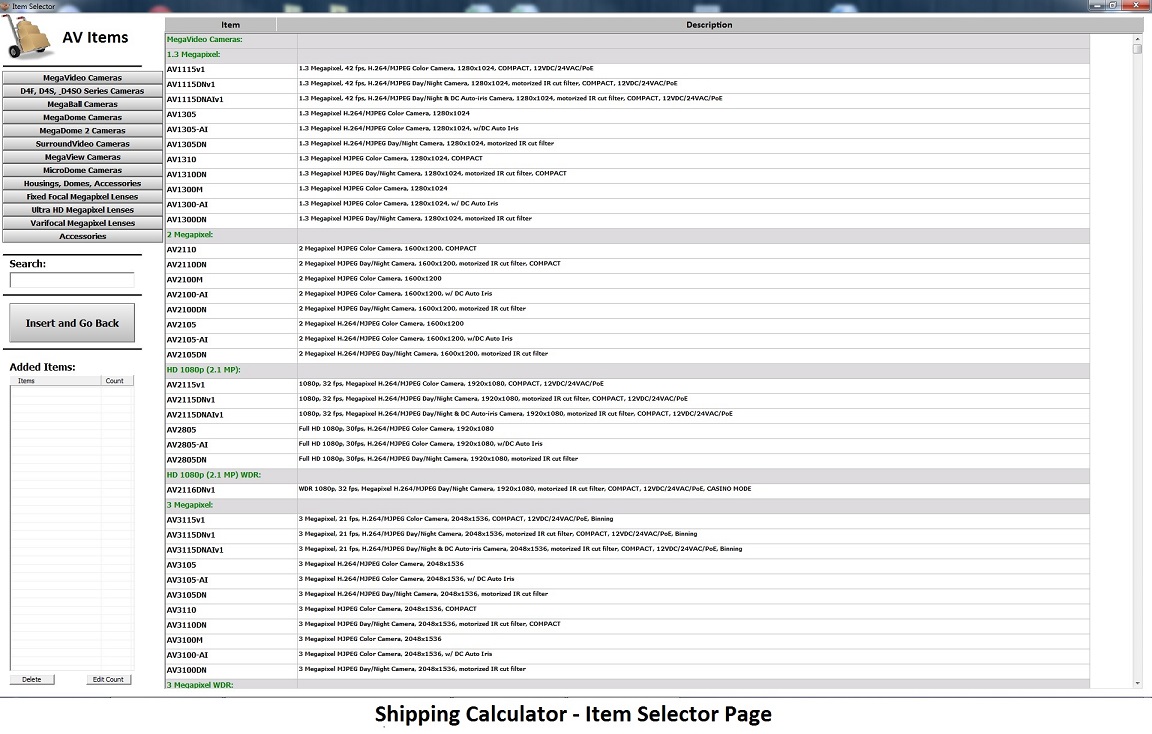

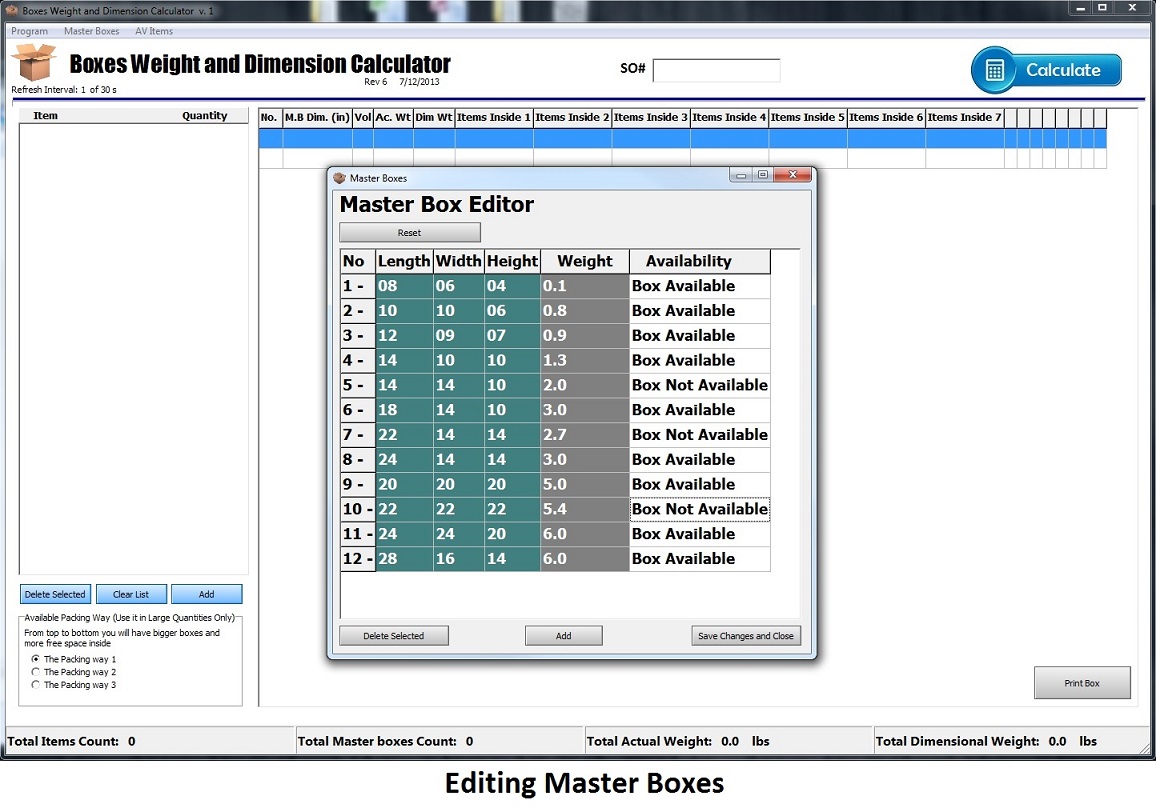

Shipping Calculator:

Description: There are always mistakes that can cost us when calculating shipping and handling fees. A big one is missing a UPS, FedEx or U.S. Postal Service DIM (dimensional) or oversize rule for large or lightweight packages. This program gives the list of the items we need to ship and tells us how many shipping cartons, what sizes and what weights they will have. That makes sales department group a lot easier and faster to estimate accurate costs for providing to the customers.

Important Features:

- It is connected to the main Database. That links the sales to Shipping departments and makes them to be aware about all items and cartons availability.

- It shows what items going to be in what boxes.

- It shows the dimension and weight of each box.

- Prints out the result with the description and SO#.

- Three optional ways to calculate for small items in big cartons.

- Makes us to be able to adjust and change the gap between the items and cartons inside the box for international shipping.

- Easy to search an item and insert to the boxes.

Below are some sample images of projects:

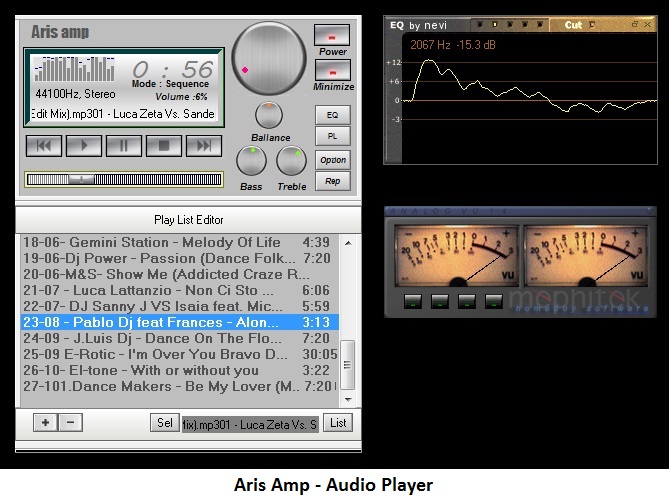

Some other Projects:

AD Automation Inc.

1408 Highland Ave. Glendale CA 91202

(818) 433-4004